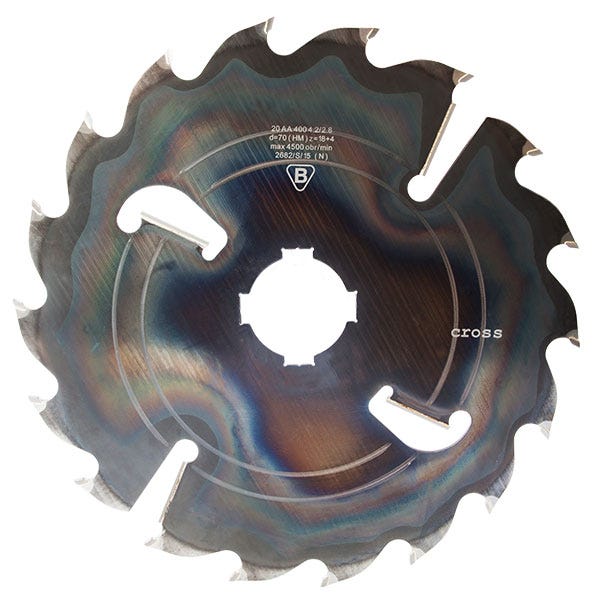

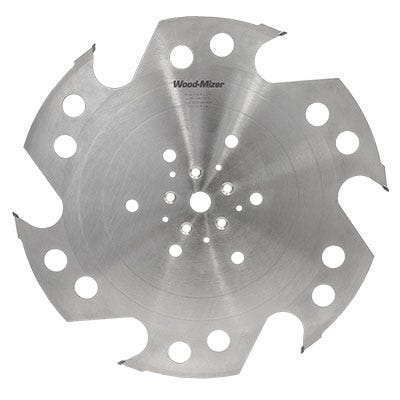

Circular Saw Blades

Multirip, ripsaw, and crosscut circular saw blades.

Our large selection of circular saw blades for solid wood cover just about every sawing application – for wet or dry softwoods and hardwoods, as well as tropical hardwoods and panels. Our blades are covered with anti-adhesive coating, which protects the blade against surface build up. Our blacktreated multirip blades deliver higher durability and has an antifriction coating that is dust and heat resistant.

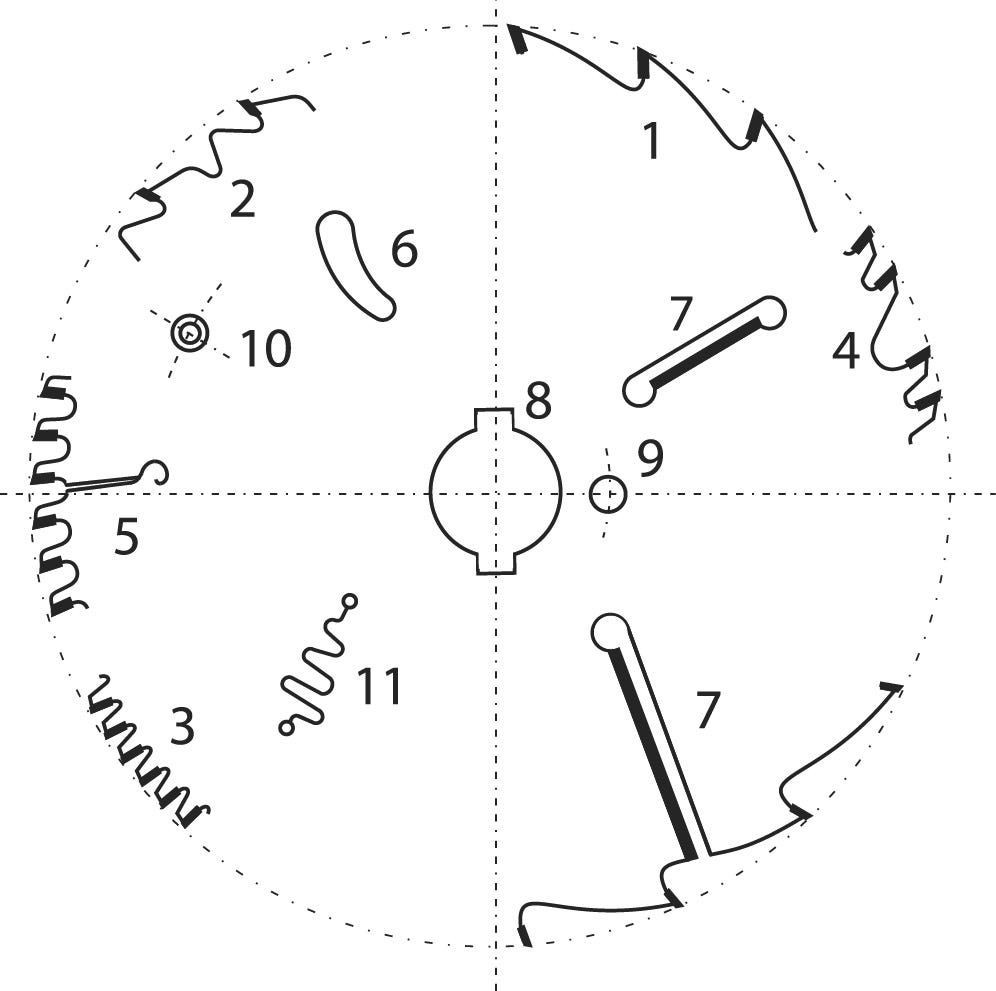

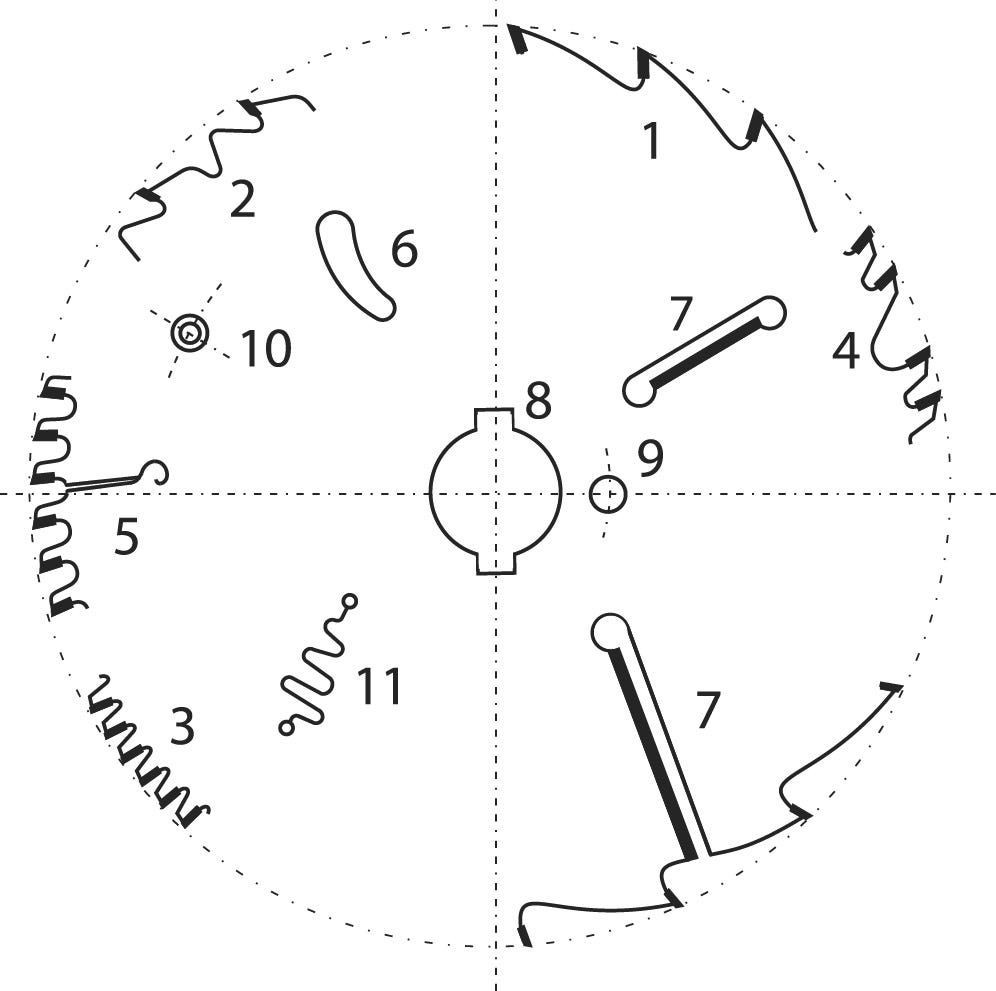

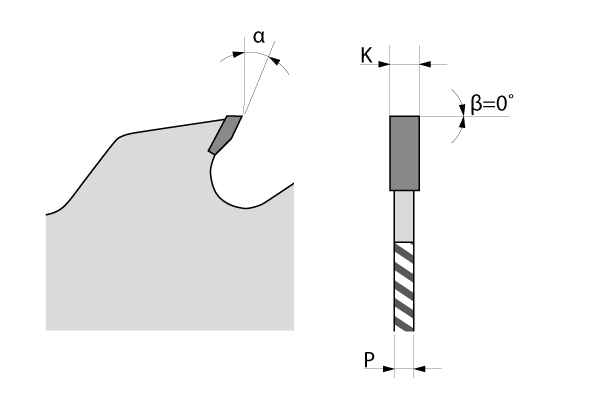

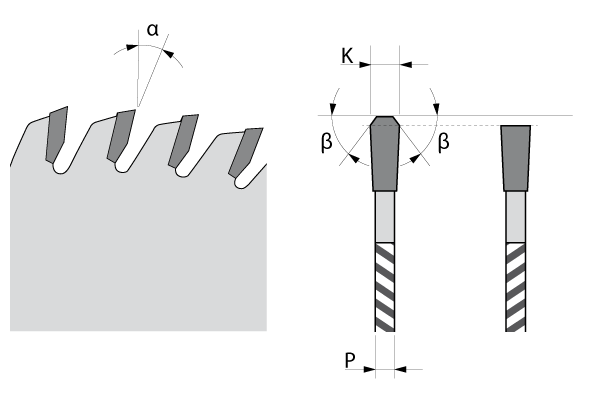

Tooth patterns and blade structure

- Teeth with positive hook angle

- Teeth with positive hook angle and anti-kickback

- Teeth with negative hook angle

- Teeth with positive hook angle and irregular pitch

- Expansion slot

- Cooling slot

- Wiper slot

- Keyway

- Pin hole

- Countersink holes

- Noise reducing laser cut

How to read circular saw blade part numbers

Example:

TM A350.016.70

| Standard order format | |

|---|---|

| TM | Tools Multi-Rip Standard - blackened |

| TR | Tools Rip |

| TC | Tools CrossCut |

| TLC | Tools Panel Sizing(for Laminated & Chipboard) |

| 350 | diameter [mm] 100-800 |

| • | |

| 16 | quantity of teeth 5-150 [pcs] |

| • | |

| 70 |

bore [mm] 16-90 |

B – medium number of teeth

C – high number of teeth

S – polished

b – blackened

c – coated

Example:

TMB350.018. 70/4.2/2.8/4R

| Special order format | |

|---|---|

| TM | Tools Multi-Rip Standard - blackened |

| TR | Tools Rip |

| TC | Tools CrossCut |

| TLC | Tools Panel Sizing(for Laminated & Chipboard) |

| 350 | diameter [mm] 100-800 |

| • | |

| 18 | quantity of teeth 5-150 [pcs] |

| • | |

| 70 | bore [mm] 16-90 |

| 4.2 | Kerf thickness [mm] |

| 2.8 | Plate thickness [mm] |

| 4R | quantity of raker teeth |

This format is useful when reordering special order blades. Use the item from your previous order to order the same blades again.

Selecting cutting parameters for different materials

| Material | Cutting speed [m/s] |

|---|---|

| Softwood | 60 - 100 |

| Wet softwood | 70 - 100 |

| Hardwood | 50 - 90 |

| Chipboard | 60 - 80 |

| MDF board | 60 - 80 |

| Hard fibreboard | 50 - 80 |

| Soft fibreboard | 60 - 100 |

| Plywood | 50 - 80 |

| Non-ferrous metals | 40 - 60 |

| Plastic | 50 - 80 |

| D[mm] | n [RPM] | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1500 | 2000 | 2800 | 3500 | 4500 | 6000 | 8000 | 10000 | 13000 | |

| 100 | 8 | 11 | 15 | 18 | 24 | 31 | 42 | 53 | 63 |

| 150 | 12 | 16 | 22 | 27 | 35 | 47 | 63 | 79 | 94 |

| 200 | 16 | 21 | 29 | 37 | 47 | 63 | 84 | 105 | |

| 250 | 20 | 26 | 37 | 46 | 59 | 79 | 105 | ||

| 300 | 24 | 32 | 44 | 55 | 71 | 94 | |||

| 350 | 28 | 37 | 51 | 64 | 82 | 110 | |||

| 400 | 32 | 42 | 59 | 73 | 94 | ||||

| 450 | 36 | 47 | 66 | 82 | 106 | ||||

| 500 | 40 | 52 | 73 | 92 | |||||

| 550 | 43 | 58 | 81 | 101 | |||||

| 600 | 47 | 63 | 88 | ||||||

| 650 | 51 | 68 | 95 | ||||||

| 700 | 55 | 73 | 103 | ||||||

Tooth patterns and blade structure

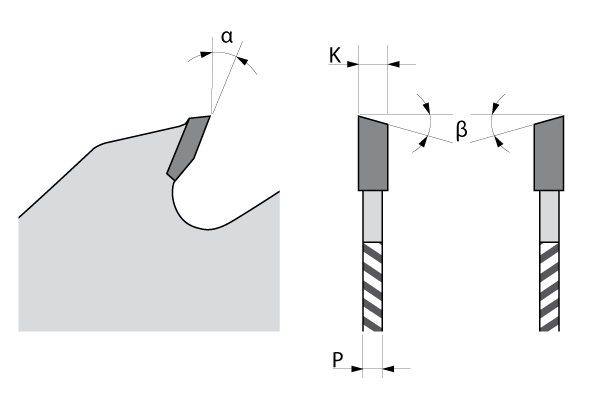

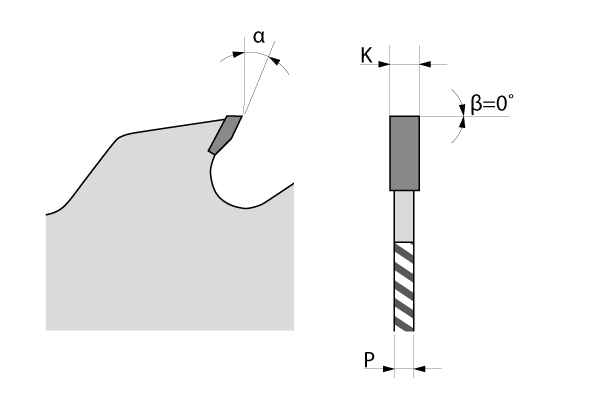

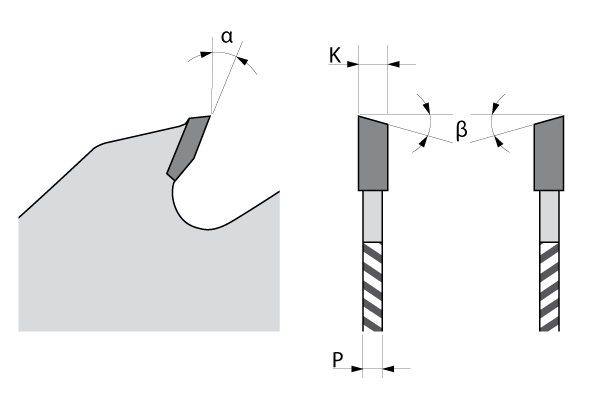

Alternate top bevel grind

Flat top grind

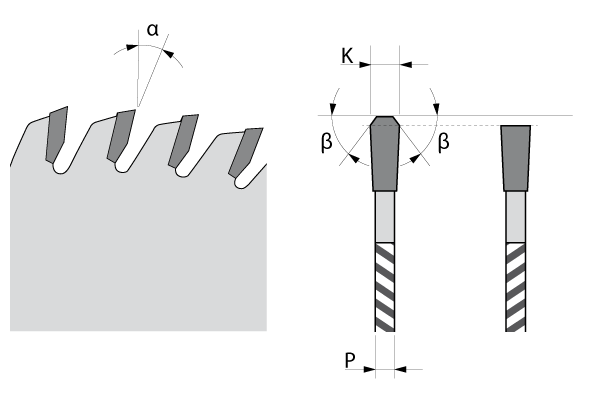

Triple chip grind (trapezoidal)

Circular Saw Blades

Multirip, ripsaw, and crosscut circular saw blades.

Our large selection of circular saw blades for solid wood cover just about every sawing application – for wet or dry softwoods and hardwoods, as well as tropical hardwoods and panels. Our blades are covered with anti-adhesive coating, which protects the blade against surface build up. Our blacktreated multirip blades deliver higher durability and has an antifriction coating that is dust and heat resistant.

Tooth patterns and blade structure

- Teeth with positive hook angle

- Teeth with positive hook angle and anti-kickback

- Teeth with negative hook angle

- Teeth with positive hook angle and irregular pitch

- Expansion slot

- Cooling slot

- Wiper slot

- Keyway

- Pin hole

- Countersink holes

- Noise reducing laser cut

How to read circular saw blade part numbers

Example:

TM A350.016.70

| Standard order format | |

|---|---|

| TM | Tools Multi-Rip Standard - blackened |

| TR | Tools Rip |

| TC | Tools CrossCut |

| TLC | Tools Panel Sizing(for Laminated & Chipboard) |

| 350 | diameter [mm] 100-800 |

| • | |

| 16 | quantity of teeth 5-150 [pcs] |

| • | |

| 70 |

bore [mm] 16-90 |

B – medium number of teeth

C – high number of teeth

S – polished

b – blackened

c – coated

Example:

TMB350.018. 70/4.2/2.8/4R

| Special order format | |

|---|---|

| TM | Tools Multi-Rip Standard - blackened |

| TR | Tools Rip |

| TC | Tools CrossCut |

| TLC | Tools Panel Sizing(for Laminated & Chipboard) |

| 350 | diameter [mm] 100-800 |

| • | |

| 18 | quantity of teeth 5-150 [pcs] |

| • | |

| 70 | bore [mm] 16-90 |

| 4.2 | Kerf thickness [mm] |

| 2.8 | Plate thickness [mm] |

| 4R | quantity of raker teeth |

This format is useful when reordering special order blades. Use the item from your previous order to order the same blades again.

Selecting cutting parameters for different materials

| Material | Cutting speed [m/s] |

|---|---|

| Softwood | 60 - 100 |

| Wet softwood | 70 - 100 |

| Hardwood | 50 - 90 |

| Chipboard | 60 - 80 |

| MDF board | 60 - 80 |

| Hard fibreboard | 50 - 80 |

| Soft fibreboard | 60 - 100 |

| Plywood | 50 - 80 |

| Non-ferrous metals | 40 - 60 |

| Plastic | 50 - 80 |

RPM for required cutting speed and tool diameter

| D[mm] | n [RPM] | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1500 | 2000 | 2800 | 3500 | 4500 | 6000 | 8000 | 10000 | 13000 | |

| 100 | 8 | 11 | 15 | 18 | 24 | 31 | 42 | 53 | 63 |

| 150 | 12 | 16 | 22 | 27 | 35 | 47 | 63 | 79 | 94 |

| 200 | 16 | 21 | 29 | 37 | 47 | 63 | 84 | 105 | |

| 250 | 20 | 26 | 37 | 46 | 59 | 79 | 105 | ||

| 300 | 24 | 32 | 44 | 55 | 71 | 94 | |||

| 350 | 28 | 37 | 51 | 64 | 82 | 110 | |||

| 400 | 32 | 42 | 59 | 73 | 94 | ||||

| 450 | 36 | 47 | 66 | 82 | 106 | ||||

| 500 | 40 | 52 | 73 | 92 | |||||

| 550 | 43 | 58 | 81 | 101 | |||||

| 600 | 47 | 63 | 88 | ||||||

| 650 | 51 | 68 | 95 | ||||||

| 700 | 55 | 73 | 103 | ||||||

Tooth patterns and blade structure

Alternate top bevel grind

Flat top grind

Triple chip grind (trapezoidal)